- Roofing screws

- Roof Fasteners & Plates

- Wood structure screws

- Bi-metal screws

- Concrete nail

- Hex head screws

- Double thread screws

- Stainless steel screws

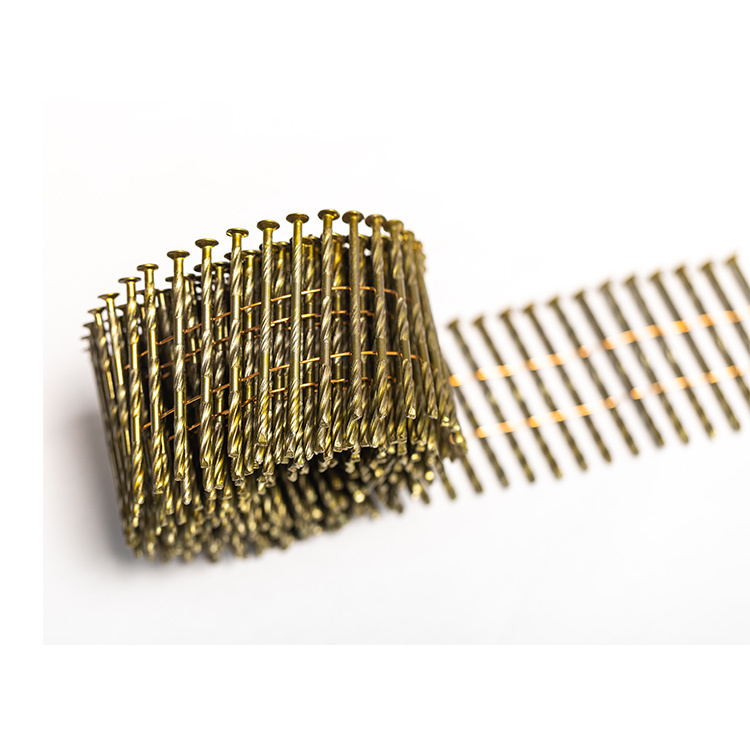

- Coil nails

- Anchor

- Metal insulation plate

- Bolt&Nut

- Concrete fastener

-

Stitching Screw

Stitching ScrewMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

Farmer Screws

Farmer ScrewsMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

Nylon Hex Washer Head

Nylon Hex Washer HeadMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

Hex Washer Head Bi-Metal Self-Drilling Screw

Hex Washer Head Bi-Metal Self-Drilling ScrewMATERIAL: SUS 300 Series Alloy Steel/Carbon Steel

SIZE: Customize

-

Hex Flange Head Bi-Metal Self-Drilling Screw

Hex Flange Head Bi-Metal Self-Drilling ScrewMATERIAL: SUS 300 Series Alloy Steel/Carbon Steel

SIZE: Customize

-

#12 Extra Heavy Duty Roofing Fastener Torx Head

#12 Extra Heavy Duty Roofing Fastener Torx HeadProduct category: Roofing Fastener

Material: 1022A wire steel

Type: Torx Head

-

Bi-Metal Self-Drilling Screw

Bi-Metal Self-Drilling ScrewMATERIAL: SUS 300 Series Alloy Steel/Carbon Steel

SIZE: Customize

-

Hex Washer Head

Hex Washer HeadMATERIAL: Carbon Steel

SIZE: M4.2 M4.8

-

Hex Washer Head

Hex Washer HeadMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

#14 Heavy Duty Roofing Fastener Phillips Truss

#14 Heavy Duty Roofing Fastener Phillips TrussProduct category: Roofing Fastener

Material: 1022A wire steel

Type: Phillips Head

-

#12 Standard Drill Point Roofing Fastener Phillips Truss

#12 Standard Drill Point Roofing Fastener Phillips TrussProduct category: Roofing Fastener

Material: 1022A wire steel

Type: Phillips Head

-

#15 Extra Heavy Duty Roofing Fastener Torx Head

#15 Extra Heavy Duty Roofing Fastener Torx HeadProduct category: Roofing Fastener

Material: 1022A wire steel

Type: Torx Head

-

#14 Extra Heavy Duty Roofing Fastener Torx Head

#14 Extra Heavy Duty Roofing Fastener Torx HeadProduct category: Roofing Fastener

Material: 1022A wire steel

Type: Torx Head

-

#14 Extra Heavy Duty Roofing Fastener

#14 Extra Heavy Duty Roofing FastenerSHDS ##14 Heavy Duty Roofing Fastener are designed to secure insulation to 16-22 gauge steel and wood decks. The fastener must acheive a penetration depth of 3/4” minimum. The fastener is also available pre-assembled with 3” Galvanized Steel Insulation Plates. Pre-assembled insulation fasteners and plates are fast to install and increase productivity in the mechanical attachment of roof insulation boards.

-

#15 Extra Heavy Duty Roofing Fastener Phillips Truss

#15 Extra Heavy Duty Roofing Fastener Phillips Truss -

Oval Barbed Metal insulation plate

Oval Barbed Metal insulation plateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

2-3/8" Barbed Metal Plate

2-3/8" Barbed Metal PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

2-3/8" Barbed Plate

2-3/8" Barbed PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

2'' Barbed Plate

2'' Barbed PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

Timber Construction Screw

Timber Construction ScrewMATERIAL: Carbon Steel

SIZE: ∅4.0 ∅4.5 ∅5.0 ∅6.0 ∅8.0 ∅10.0

-

China White Drywall Screws

China White Drywall ScrewsProduct category: Roofing Fastener

Material: 1022A wire steel

Type: Torx Head

-

2-3/8" Barbed Plate

2-3/8" Barbed PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

SHIP-0683 3'' insulation plate

SHIP-0683 3'' insulation plateRoof Insulation Plates are used for roof system attachment to steel and wood roof decks.The circular and reinforcing ribs provide increased performance to resist wind uplift forces.

The plates are made of Galvalume coated steel which protected with high-performance alloy of aluminumand zinc, provide excellent corrosion protection.

-

SHBP-0660 2.36''barbed plate

SHBP-0660 2.36''barbed plateBarbed seam Plates are used for roof system attachment to steel and wood roof decks.Thecircular and reinforcing ribs provide increased performance to resist wind uplift forces.Theplates are made of Galvalume coated steel which protected with high-performance alloy ofaluminum and zinc, provide excellent corrosion protection.

-

SHBP-0650S 2'' barbed plate

SHBP-0650S 2'' barbed plateBarbed seam Plates are used for roof system attachment to steel and wood roof decks. Thecircular and reinforcing ribs provide increased performance to resist wind uplift forces.Theplates are made of Galvalume coated steel which protected with high-performance alloy ofaluminum and zinc, provide excellent corrosion protection.

-

deck coil nails

deck coil nailsProduct category: Fasteners/Coil Nails

Material: Steel

Specification: optional

Usage: Pallet;Furniture;Package;Woodwork

Origin: China

-

Screw coil nail

Screw coil nailProduct category: Fasteners/Coil Nails

Material: Steel

Specification: optional

Usage: Pallet;Furniture;Package;Woodwork

Origin: China

-

Countersunk Head

Countersunk HeadMATERIAL: Carbon Steel

SIZE: M3.5 M3.9 M4.2 M4.8

-

Galvanized coil roofing nails

Galvanized coil roofing nailsProduct category: Fasteners/Coil Nails

Material: Steel

Specification: optional

Usage: Pallet;Furniture;Package;Woodwork

Origin: China

-

Concrete Spike Fastener

Concrete Spike FastenerMATERIAL: Carbon Steel

-

-1-1716533802016.jpg) All Purpose Roofing Fastener (#14)

All Purpose Roofing Fastener (#14)MATERIAL: Carbon Steel

-

Countersunk Wings

Countersunk WingsMATERIAL: Carbon Steel

SIZE: M3.5 M3.9 M4.2 M4.8

-

Pan Head

Pan HeadMATERIAL: Carbon Steel

SIZE: M3.5 M3.9 M4.2 M4.8

-

Truss Head

Truss HeadMATERIAL: Carbon Steel

SIZE: M4.2 M4.8

-

Hex Washer Flange

Hex Washer FlangeMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

Bugle Head

Bugle HeadMATERIAL: Carbon Steel

SIZE: M3.5 M4.2 M4.8

-

Wafer Head

Wafer HeadMATERIAL: Carbon Steel

SIZE: M4.8-M5.5

-

Truss Head Phillips Recess Bi-Metal Self-Drilling Screw

Truss Head Phillips Recess Bi-Metal Self-Drilling ScrewMATERIAL: SUS 300 Series Alloy Steel/Carbon Steel

SIZE: Customize

-

Pan Head Phillips Recess Bi-Metal Self-Drilling Screw

Pan Head Phillips Recess Bi-Metal Self-Drilling ScrewMATERIAL: SUS 300 Series Alloy Steel/Carbon Steel

SIZE: Customize

-

Pan Head Bi-Metal Self-Drilling Screw

Pan Head Bi-Metal Self-Drilling ScrewMATERIAL: SUS 300 Series Alloy Steel/Carbon Steel

SIZE: Customize

-

Hex Washer Head Bi-Metal Self-Drilling Screw

Hex Washer Head Bi-Metal Self-Drilling ScrewMATERIAL: SUS 300 Series Alloy Steel/Carbon Steel

SIZE: Customize

-

Flat Head Phillips Recess Bi-Metal Self-Drilling Screw

Flat Head Phillips Recess Bi-Metal Self-Drilling ScrewMATERIAL: SUS 300 Series Alloy Steel/Carbon Steel

SIZE: Customize

-

Round Washer Head

Round Washer HeadMATERIAL: Carbon Steel

SIZE: M4.2 M4.8 M5.5

-

Fast Wood Screw

Fast Wood ScrewMATERIAL: Carbon Steel

SIZE: M4.8 M5.5

-

Concrete &Masonry Application

Concrete &Masonry ApplicationMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

Countersunk Head

Countersunk HeadMATERIAL: Carbon Steel

SIZE: M3.9 M4.2 M4.8 M5.5

-

Pan Head

Pan HeadMATERIAL: Carbon Steel

SIZE: M3.9 M4.2 M4.8 M5.5

-

Truss Head

Truss HeadMATERIAL: Carbon Steel

SIZE: M3.9 M4.2 M4.8 M5.5

-

Hex Washer Head

Hex Washer HeadMATERIAL: Carbon Steel

SIZE: M4.8 M5.5 M6.3

-

Hexagon Head

Hexagon HeadMATERIAL: Carbon Steel

SIZE: M4.8 M5.5 M6.3

-

Hex Washer Flange

Hex Washer FlangeMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

Truss Head

Truss HeadMATERIAL: Carbon Steel

SIZE: M4.2 M4.8

-

Pan Head

Pan HeadMATERIAL: Carbon Steel

SIZE: M3.5 M3.9 M4.2 M4.8

-

Nylon Frame Fixing Anchor

Nylon Frame Fixing AnchorMATERIAL: Carbon Steel

SIZE: 6-3.9-P1.818-5.6-P2.2 10-6.6-P2.82

-

-1683536390043.jpg) Hex Washer Flange (SD500)

Hex Washer Flange (SD500)MATERIAL: Carbon Steel

SIZE: M5.5

-

Slotted Hex Washer Head

Slotted Hex Washer HeadMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

Double Thread

Double ThreadMATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

Hex Washer Flange

Hex Washer FlangeMATERIAL: Carbon Steel

SIZE: M6.3

-

-1683537398249.jpg) Crest Fixing Screw(Roofing Screw)

Crest Fixing Screw(Roofing Screw)MATERIAL: Carbon Steel

SIZE: M5.5 M6.3

-

-1683537507870.jpg) Wafer Head Screw(Roofing Screw)

Wafer Head Screw(Roofing Screw)MATERIAL: Carbon Steel

SIZE: M5.5M6.3 M7.1

-

Drywall Screws

Drywall ScrewsMATERIAL: Carbon Steel

SIZE: M3.5 M3.9 M4.8

-

Chipboard Screws

Chipboard ScrewsMATERIAL: Carbon Steel

SIZE: M4-P1.8 M5-P2.2 M6-P2.6

-

CSK Head

CSK HeadMATERIAL: Carbon Steel

DIAMETER: M3.5 M3.9 M4.2 M4.8 M5.5

-

Wafer Head

Wafer HeadMATERIAL: Carbon Steel

DIAMETER:M3.5 M3.9 M4.2 M4.8 M5.5

-

Machine Screw Phillips Flat Head

Machine Screw Phillips Flat HeadMATERIAL: Carbon Steel

DIAMETER:M3.5 M4.0

-

Socket Flat Head

Socket Flat HeadMATERIAL: Carbon Steel

DIAMETER:M4 M5

-

Self Drilling Lag Bolts

Self Drilling Lag BoltsProduct category: Fasteners/Bolt&Nut

Material: STAINLESS STEEL

Head type: Open End

Brand Name: SHENGHANG

Place of Origin: Shandong, China

-

Hexagon Flanged Drill Tail Screw

Hexagon Flanged Drill Tail ScrewProduct category: Fasteners/Screws

Material: Stainless Steel

Type: Hex Head

Contact: Ordinary Bolts

-

Oval Insulation Plate

Oval Insulation PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

3” Ribbed Plate

3” Ribbed PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

3” Insulation Plate

3” Insulation PlateProduct category: Insulation plate

Weld plates are an essential part of any welding project. There are a variety of welding plates on the market, each with its own characteristics. A very popular type of welding plate is the induction welding plate. The induction welding plate is made of high-quality steel and is very strong

-

2.3x 40mm 15 degree smooth flat plate galvanized surface wood pallet nails Coil nails

2.3x 40mm 15 degree smooth flat plate galvanized surface wood pallet nails Coil nailsProduct category: Fasteners/Coil Nails

Material: Steel

Specification: optional

Usage: Pallet;Furniture;Package;Woodwork

Origin: China

-

2.5x 50mm mm 15 degree wire finishing coil nails

2.5x 50mm mm 15 degree wire finishing coil nailsProduct category: Fasteners/Coil Nails

Material: Steel

Specification: optional

Usage: Pallet;Furniture;Package;Woodwork

Origin: China

-

Yellow plain wire tray coil nails

Yellow plain wire tray coil nailsProduct category: Fasteners/Coil Nails

Material: Steel

Specification: optional

Usage: Pallet;Furniture;Package;Woodwork

Origin: China

-

M30 10.9 stud bolts of various weight classes

M30 10.9 stud bolts of various weight classesProduct category: Fasteners/Bolt&Nut

Measurement system: Metric, Imperial (Inch)

Brand Name: SHENGHANG

Standard: GB

-

Galvanized steel 3PCS 4 pcs fixed anchor bolts with bolts and washers

Galvanized steel 3PCS 4 pcs fixed anchor bolts with bolts and washersProduct category: Fasteners/Anchor

Finish: Bright(Uncoated)

System of Measurement: INCH

Place of Origin: Shandong, China

Brand Name: SHENGHANG

-

Anchor

AnchorProduct category: Fasteners/Anchor

Material: Steel

Capacity: 5000N, High Load Capacity

Standard: ISO

Installation Site: Open Field

-

RS PRO Embedded anchor, M16, steel, 65mm long, 20mm fixed hole diameter

RS PRO Embedded anchor, M16, steel, 65mm long, 20mm fixed hole diameterProduct category: Fasteners/Anchor

Finish: Bright(Uncoated)

System of Measurement: INCH

Capacity: 5000N, High Load Capacity

Standard: ISO

-

roofing coil nails

roofing coil nailsProduct category: Fasteners/Coil Nails

Material: Steel

Specification: optional

Usage: Pallet;Furniture;Package;Woodwork

Origin: China

-

TPO Insulation plate

TPO Insulation plateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

PVC Insulation plate

PVC Insulation plateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

304 stainless steel hexagon thin nuts

304 stainless steel hexagon thin nutsProduct category: Fasteners/Bolt&Nut

Treating: Cleaning

OEM: Accetable

Surface treatment: Plain

Place of Origin: Shandong, China

-

Steel Structure Bolt

Steel Structure BoltProduct category: Fasteners/Bolt&Nut

Measurement system: Metric, Imperial (Inch)

Brand Name: SHENGHANG

OEM: Accetable

Surface treatment: Plain

-

Square Nut

Square NutProduct category: Fasteners/Bolt&Nut

Material: STAINLESS STEEL

Head type: Open End

Brand Name: SHENGHANG

Place of Origin: Shandong, China

-

Nylon Lock Nut

Nylon Lock NutProduct category: Fasteners/Bolt&Nut

Measurement system: Metric, Imperial (Inch)

Brand Name: SHENGHANG

Standard: GB

-

Hexagon Socket Bolt

Hexagon Socket BoltProduct category: Fasteners/Bolt&Nut

Material: STAINLESS STEEL

Head type: Open End

Treating: Cleaning

OEM: Accetable

-

Hex Nut

Hex NutProduct category: Fasteners/Bolt&Nut

Treating: Cleaning

OEM: Accetable

Surface treatment: Plain

Place of Origin: Shandong, China

-

Hex Flange Nut

Hex Flange NutProduct category: Fasteners/Bolt&Nut

Measurement system: Metric, Imperial (Inch)

Brand Name: SHENGHANG

OEM: Accetable

Surface treatment: Plain

-

JM Brand Yellow Zinc Plated ASTM A193 B7 3/4 7/8 Inch By 6 5 Inch Stud Bolt & Nuts

JM Brand Yellow Zinc Plated ASTM A193 B7 3/4 7/8 Inch By 6 5 Inch Stud Bolt & NutsProduct category: Fasteners/Bolt&Nut

Material: STAINLESS STEEL

Head type: Open End

Brand Name: SHENGHANG

Place of Origin: Shandong, China

-

Hex Bolt With Washer

Hex Bolt With WasherProduct category: Fasteners/Bolt&Nut

Measurement system: Metric, Imperial (Inch)

Brand Name: SHENGHANG

Standard: GB

Head type: Open End

-

Hex Bolt With Flange

Hex Bolt With FlangeProduct category: Fasteners/Bolt&Nut

Material: STAINLESS STEEL

Head type: Open End

Treating: Cleaning

OEM: Accetable

-

Stainless steel class 304 u bolts with two washers and nut u clamp M5*78

Stainless steel class 304 u bolts with two washers and nut u clamp M5*78Product category: Fasteners/Bolt&Nut

Treating: Cleaning

OEM: Accetable

Surface treatment: Plain

Place of Origin: Shandong, China

-

Hex head bolts of steel DIN933

Hex head bolts of steel DIN933Product category: Fasteners/Bolt&Nut

Material: STAINLESS STEEL

Head type: Open End

Brand Name: SHENGHANG

Place of Origin: Shandong, China

-

Wedge Anchor

Wedge AnchorProduct category: Fasteners/Anchor

Finish: Bright(Uncoated)

System of Measurement: INCH

Place of Origin: Shandong, China

-

Sleeve Anchor

Sleeve AnchorProduct category: Fasteners/Anchor

Finish: Bright(Uncoated)

System of Measurement: INCH

Place of Origin: Shandong, China

Brand Name: SHENGHANG

-

Heavy Duty Shield Anchor

Heavy Duty Shield AnchorProduct category: Fasteners/Anchor

Material: Steel

Capacity: 5000N, High Load Capacity

Standard: ISO

Installation Site: Open Field

-

Drop In Anchor With Flange

Drop In Anchor With FlangeProduct category: Fasteners/Anchor

Finish: Bright(Uncoated)

System of Measurement: INCH

Place of Origin: Shandong, China

-

Cut Anchor Bolt

Cut Anchor BoltProduct category: Fasteners/Anchor

Finish: Bright(Uncoated)

System of Measurement: INCH

Place of Origin: Shandong, China

Brand Name: SHENGHANG

-

DIN571 hexagon head wood screws with full thread

DIN571 hexagon head wood screws with full threadProduct category: Fasteners/Screws

Material: Stainless Steel

Type: Hex Head

Contact: Ordinary Bolts

-

Galvanized double flathead fiberboard screws

Galvanized double flathead fiberboard screwsProduct category: Fasteners/Screws

Material: Carbon Steel/Stainless Steel

Type: Countersunk

Slot: Fork

Contact: Ordinary Bolts

head shape: round

-

Countersunk flat head particleboard screws with carbon steel C1022

Countersunk flat head particleboard screws with carbon steel C1022Product category: Fasteners/Screws

Material: Stainless Steel

Contact: Ordinary Bolts

Material: Carbon Steel/Stainless Steel

-

Particleboard screws pz2 Cornmeal drive wood screws

Particleboard screws pz2 Cornmeal drive wood screwsProduct category: Fasteners/Screws

Material: Stainless Steel

Contact: Ordinary Bolts

head shape: round

-

stainless self drilling screw

stainless self drilling screwProduct category: Fasteners/Screws

Material: Carbon Steel/Stainless Steel

Type: Countersunk

Slot: Fork

Contact: Ordinary Bolts

head shape: round

-

stainless Self Drilling Screw with hex washer head

stainless Self Drilling Screw with hex washer headProduct category: Fasteners/Screws

Material: Carbon Steel/Stainless Steel

Type: Hex Head

Contact: Ordinary Bolts

Application: machinery, chemical industry, environmental protection, construction, electronics, etc.

-

slotted hex self tapping screws

slotted hex self tapping screwsProduct category: Fasteners/Screws

Material: Carbon Steel

Type: Hex Head

Slot: Pentalobal

-

slotted hex self tapping screws

slotted hex self tapping screwsProduct category: Fasteners/Screws

Materials: Carbon Steel, Stainless Steel, Aluminum, Brass

Features: Good anti-corrosion ability

Application: machinery, chemical industry, environmental protection, construction, electronics, etc.

-

self tapping screw with hex washer head

self tapping screw with hex washer headProduct category: Fasteners/Screws

Contact: Ordinary Bolts

Material: Carbon Steel/Stainless Steel

head shape: round

-

Coarse thread drywall screw

Coarse thread drywall screwProduct category: Fasteners/Screws

Materials: Carbon Steel, Stainless Steel, Aluminum, Brass

Type: Hex Head

Slot: Pentalobal

-

Black oxidized countersunk head screws self tapping drywall screws

Black oxidized countersunk head screws self tapping drywall screwsProduct category: Fasteners/Screws

Material: Carbon Steel/Stainless Steel

Type: Hex Head

Features: Good anti-corrosion ability

Application: machinery, chemical industry, environmental protection, construction, electronics, etc.

-

self drilling screw with hex washer head

self drilling screw with hex washer headProduct category: Fasteners/Screws

Material: Carbon Steel/Stainless Steel

Contact: Ordinary Bolts

Head shape: round

Type: Countersunk

-

Double countersunk head self tapping particleboard screws

Double countersunk head self tapping particleboard screwsProduct category: Fasteners/Screws

Material: Steel

Measurement system: Metric

Head Style: Flat

-

self drilling screw with hex washer head

self drilling screw with hex washer headProduct category: Fasteners/Screws

Type: Hex Head

Slot: Pentalobal

Features: Good anti-corrosion ability

Application: machinery, chemical industry, environmental protection, construction, electronics, etc.

-

self drilling screw with hex washer head

self drilling screw with hex washer headProduct category: Fasteners/Screws

Place of Origin: Shandong, China

Brand Name: SHENGHANG

Model Number: Custom size

Product name: Self Drilling Screw

-

Self Drilling Screw with countersunk head

Self Drilling Screw with countersunk headProduct category: Fasteners/Screws

Brand Name: SHENGHANG

Model Number: Custom size

Size: Customized Size

Packing: Carton+pallet

-

Hexagon socket set screws, flat end, class 12.9

Hexagon socket set screws, flat end, class 12.9Product category: Fasteners/Screws

Material: Steel

Measurement system: Metric

Brand Name: SHENGHANG

Model Number: Custom size

-

Black head fiber cement board screws Fiber cement board drywall screws

Black head fiber cement board screws Fiber cement board drywall screwsProduct category: Fasteners/Screws

Place of Origin: Shandong, China

Measurement system: Metric

Head Style: Flat

-

phillips head roofing screw

phillips head roofing screwProduct category: Fasteners/Screws

Material: Steel

Measurement system: Metric

Head Style: Flat

-

Drywall Screw with phillips head

Drywall Screw with phillips headProduct category: Fasteners/Screws

Place of Origin: Shandong, China

Brand Name: SHENGHANG

Model Number: Custom size

Product name: Self Drilling Screw

-

Truss head self drilling screw

Truss head self drilling screwProduct category: Fasteners/Screws

Brand Name: SHENGHANG

Model Number: Custom size

Size: Customized Size

Packing: Carton+pallet

-

Drywall Screw with drill point

Drywall Screw with drill pointProduct category: Fasteners/Screws

Material: Steel

Measurement system: Metric

Brand Name: SHENGHANG

Model Number: Custom size

-

Chipboard Screw

Chipboard ScrewProduct category: Fasteners/Screws

Material: Steel

Measurement system: Metric

Head Style: Flat

-

Self Tapping Screws Menards

Self Tapping Screws MenardsProduct category: Fasteners/Screws

Material: Stainless Steel

Type: Hex Head

Contact: Ordinary Bolts

-

Patta Self Drilling Screws

Patta Self Drilling ScrewsProduct category: Fasteners/Screws

Material: Carbon Steel/Stainless Steel

Type: Hex Head

Contact: Ordinary Bolts

Application: machinery, chemical industry, environmental protection, construction, electronics, etc.

-

OEM Manufacturer Self Drilling Concrete Screws

OEM Manufacturer Self Drilling Concrete ScrewsProduct category: Fasteners/Screws

Type: Hex Head

Slot: Pentalobal

Features: Good anti-corrosion ability

Application: machinery, chemical industry, environmental protection, construction, electronics, etc.

-

Self Drilling Screws For Steel Beam

Self Drilling Screws For Steel BeamProduct category: Fasteners/Screws

Material: Carbon Steel/Stainless Steel

Type: Countersunk

Slot: Fork

Contact: Ordinary Bolts

head shape: round

-

Fine thread drywall screw

Fine thread drywall screwProduct category: Fasteners/Screws

Material: Steel

Measurement system: Metric

Brand Name: SHENGHANG

Model Number: Custom size

-

Self Drilling Concrete Screws

Self Drilling Concrete ScrewsProduct category: Fasteners/Screws

Material: Stainless Steel

Type: Hex Head

Contact: Ordinary Bolts

-

#14 Extra Heavy Duty Roofing Fastener

#14 Extra Heavy Duty Roofing FastenerSHDS ##14 Heavy Duty Roofing Fastener are designed to secure insulation to 16-22 gauge steel and wood decks. The fastener must acheive a penetration depth of 3/4” minimum. The fastener is also available pre-assembled with 3” Galvanized Steel Insulation Plates. Pre-assembled insulation fasteners and plates are fast to install and increase productivity in the mechanical attachment of roof insulation boards.

-

Oval Barbed Metal insulation plate

Oval Barbed Metal insulation plateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

#15 Extra Heavy Duty Roofing Fastener Phillips Truss

#15 Extra Heavy Duty Roofing Fastener Phillips Truss -

2-3/8" Barbed Metal Plate

2-3/8" Barbed Metal PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

#14 Heavy Duty Roofing Fastener Phillips Truss

#14 Heavy Duty Roofing Fastener Phillips TrussProduct category: Roofing Fastener

Material: 1022A wire steel

Type: Phillips Head

-

2'' Barbed Plate

2'' Barbed PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

#15 Extra Heavy Duty Roofing Fastener Torx Head

#15 Extra Heavy Duty Roofing Fastener Torx HeadProduct category: Roofing Fastener

Material: 1022A wire steel

Type: Torx Head

-

SHIP-0683 3'' insulation plate

SHIP-0683 3'' insulation plateRoof Insulation Plates are used for roof system attachment to steel and wood roof decks.The circular and reinforcing ribs provide increased performance to resist wind uplift forces.

The plates are made of Galvalume coated steel which protected with high-performance alloy of aluminumand zinc, provide excellent corrosion protection.

-

phillips head roofing screw

phillips head roofing screwProduct category: Fasteners/Screws

Material: Steel

Measurement system: Metric

Head Style: Flat

-

PVC Insulation plate

PVC Insulation plateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

TPO Insulation plate

TPO Insulation plateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

3” Insulation Plate

3” Insulation PlateProduct category: Insulation plate

Weld plates are an essential part of any welding project. There are a variety of welding plates on the market, each with its own characteristics. A very popular type of welding plate is the induction welding plate. The induction welding plate is made of high-quality steel and is very strong

-

3” Ribbed Plate

3” Ribbed PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

Oval Insulation Plate

Oval Insulation PlateProduct category: Insulation plate

Welding plates are an important part of any welding project. There are a variety of weld plates available on the market, each with its own set of benefits and drawbacks. One type of weld plate that is becoming increasingly popular is induction weld plates. Induction weld plates are made of high-quality steel and are specifically designed for welding. They are easy to use and provide great results.

-

SHBP-0650S 2'' barbed plate

SHBP-0650S 2'' barbed plateBarbed seam Plates are used for roof system attachment to steel and wood roof decks. Thecircular and reinforcing ribs provide increased performance to resist wind uplift forces.Theplates are made of Galvalume coated steel which protected with high-performance alloy ofaluminum and zinc, provide excellent corrosion protection.

-

SHBP-0660 2.36''barbed plate

SHBP-0660 2.36''barbed plateBarbed seam Plates are used for roof system attachment to steel and wood roof decks.Thecircular and reinforcing ribs provide increased performance to resist wind uplift forces.Theplates are made of Galvalume coated steel which protected with high-performance alloy ofaluminum and zinc, provide excellent corrosion protection.

0086 311-66105793

0086 311-66105793

15076176199

15076176199